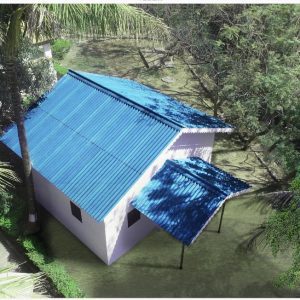

Pre-engineered buildings (PEBs) are becoming the preferred choice for industries, warehouses, and commercial spaces across India. Their speed of construction, cost savings, and long-term durability make them stand out. But what exactly goes into installing a PEB? Let’s break down the key stages step by step.

Understanding the Pre-Engineered Building (PEB) Process

Pre-engineered buildings (PEBs) are changing the way India builds. Unlike traditional construction, which takes months or even years, PEBs are faster, cost-effective, and highly efficient. Every component is manufactured in a factory and then assembled on-site, which reduces errors, saves time, and ensures consistent quality. This streamlined approach makes PEBs one of the most reliable modern building solutions.

Stage 1 – Planning and Design

The first stage of PEB installation begins with understanding project needs. The design team works closely with the client to define building size, layout, and functionality. Factors such as load requirements, wind resistance, and future expansion possibilities are also considered. Proper planning ensures that the structure will be both safe and efficient.

Stage 2 – Detailed Drawings and Approvals

Once the design is final, engineers prepare detailed structural drawings. These include layouts for columns, beams, roofing, and wall cladding. Approval from the client and necessary authorities is obtained at this stage. Accurate drawings are the backbone of smooth PEB installation, as they avoid confusion during fabrication and assembly.

Stage 3 – Factory Fabrication

Unlike traditional construction, where materials are cut and welded on-site, PEB structures are fabricated in a controlled factory environment. Advanced machines ensure precision in cutting, welding, and drilling. This not only improves quality but also minimises wastage. Once complete, the fabricated components are packaged and transported to the site.

Stage 4 – Site Preparation and Civil Foundation

While components are being fabricated, site preparation begins. This includes leveling the ground, setting up utilities, and laying a strong civil foundation. A good foundation is critical as it supports the entire PEB structure. Since foundation work and fabrication can happen simultaneously, overall project timelines are reduced.

Stage 5 – On-Site Assembly and Erection

This is where the building takes shape. Fabricated parts are lifted and assembled using cranes and bolted together as per the design. Roof panels, wall cladding, and insulation are then added. The modular nature of PEBs makes this stage quick and systematic compared to conventional building methods.

Stage 6 – Final Check and Project Delivery

The last stage involves a thorough inspection of the entire structure. Engineers check for alignment, safety, and finishing quality. Once approved, the building is handed over to the client, ready for use. This structured process ensures timely delivery without compromising on durability.

Why Choose Everest as Your PEB Partner?

Everest Industries is one of the leading PEB structure manufacturer in India. With decades of expertise, advanced technology, and a wide portfolio of successful projects, Everest ensures precision at every stage of PEB installation. From design and fabrication to erection and delivery, Everest provides end-to-end solutions that are durable, cost- effective, and customized for diverse industries.

Building Smarter with PEBs

The PEB installation process is systematic, efficient, and reliable compared to traditional construction methods. Each stage—from planning to project delivery—plays a vital role in ensuring strength and speed. As a trusted PEB structure manufacturer, Everest Industries offers modern solutions that deliver durability, safety, and long-term value. Choosing Everest means choosing a partner that builds for today and tomorrow.

FAQs

1. How long does it take to complete a PEB project?

Depending on size and complexity, a PEB project can be completed in a few weeks to a few months, which is much faster than conventional construction.

2. Why are PEB structures better than conventional ones?

PEBs are faster to build, more cost-effective, and offer higher precision since components are pre-fabricated in factories. They also allow easy future expansion.

3. What is the life expectancy of a PEB structure?

A well-maintained PEB structure can last 30–50 years, depending on design, usage, and environmental conditions.