Pre-engineered buildings (PEB) are revolutionizing the construction industry, offering a smarter, faster, and more sustainable alternative to traditional building methods. As India’s infrastructure continues to grow, these pre-engineered solutions are becoming the go-to choice for businesses across various sectors. The efficiency and customisation offered by PEB building design make them a future-forward option for any construction project.

What is a pre-engineered building?

A pre-engineered building is a structure that is designed and manufactured in a factory before being shipped to the construction site for assembly. Unlike traditional buildings, where all processes happen on-site, the PEB construction method involves producing all structural components under controlled factory conditions. These components are then transported to the site and bolted together, resulting in a streamlined and highly efficient building process. This system offers a comprehensive building solution, encompassing the structural frame, walls, and roof cladding.

Advantages of pre-engineered buildings

The growing popularity of pre-engineered buildings in India is due to their significant benefits over traditional construction.

1. Cost-effective

PEB systems reduce costs in several ways. The factory-controlled manufacturing process minimizes waste, and the mass production of components lowers material costs. Additionally, the faster erection time on-site significantly reduces labor expenses, making it a budget-friendly choice.

2. Durable

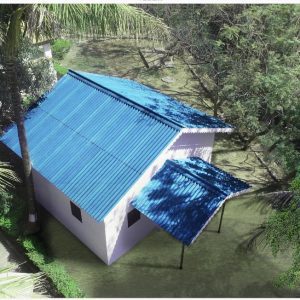

Constructed primarily from high-strength steel, pre-engineered steel buildings are incredibly robust. They are designed to withstand harsh weather conditions, from heavy rain to high winds and even seismic activity. The quality of materials and fabrication is consistently high due to the controlled factory environment.

3. Flexible

One of the key advantages of pre-engineered buildings is their design flexibility. They can be easily expanded by adding more bays. The structures allow for large, clear spans without interior support columns, providing vast, unobstructed space ideal for various applications like warehouses and factories.

4. Environmentally friendly

Steel is one of the most recycled materials in the world. The manufacturing process for pre-engineered solutions is highly efficient, producing minimal waste. The lightweight nature of the components also reduces transportation emissions, making PEB a greener choice for construction.

Major components of pre-engineered steel buildings

Understanding the key peb components helps appreciate the ingenuity behind these structures. They are broadly categorized into primary, secondary, sheeting, and accessories.

1. Primary PEB components

These form the main skeleton of the building and bear the primary loads.

1.1 Mainframe

The mainframe is the principal steel structure that provides the building’s core strength and stability. It consists of rigid frames comprising columns and rafters.

1.2 Columns

These are the vertical members of the mainframe that transfer loads from the roof down to the foundation. They are typically I-beam sections.

1.3 Rafters

Rafters are the sloping beams that form the roof structure. They connect to the columns and support the secondary framing members.

2. Secondary PEB components

These elements support the primary frame and transfer loads from the external surfaces to it.

2.1 Purlins and girts

Purlins are horizontal structural members that are placed on the rafters to support the roof sheeting. Girts are similar members used on the walls to support the wall cladding.

2.2 Eave struts

These are struts placed at the eave line of the building, where the roof and side walls meet, providing crucial support and connection at this junction.

2.3 Bracings

Bracings, typically in the form of rods or cables, are essential for stabilizing the building against lateral forces like wind and earthquakes. They are installed in the roof and walls to ensure the structure’s rigidity.

3. Sheeting or cladding

This is the external skin of the building. Steel sheets are fixed to the purlins and girts to cover the roof and walls, protecting the interior from the elements and providing insulation.

4. Accessories

PEBs can be customized with a wide range of accessories to enhance functionality and aesthetics. This includes doors, windows, skylights for natural lighting, ventilators and decorative canopies.

Applications of Pre-Engineered Buildings

The versatility of PEB building design makes them suitable for a wide array of applications across different sectors:

- Industrial: Warehouses, factories and manufacturing plants benefit from the large, column-free spaces that PEBs offer, allowing for efficient movement of goods and machinery.

- Commercial: Showrooms, supermarket and office buildings are built quickly using PEBs, enabling businesses to become operational faster.

- Agricultural: Structures like poultry farms, barns and storage sheds are cost-effective and durable, protecting valuable assets from the elements.

- Institutional: Schools, auditoriums, and community halls can be constructed efficiently, meeting the growing need for public infrastructure.

- Infrastructure: PEBs are widely used for building metro stations, airport hangars and railway platform shelters due to their robustness and rapid assembly.

Summary

Pre-engineered buildings mark a major step forward in construction technology. Their blend of affordability, speed, durability and sustainability makes them a top choice for today’s projects. As India keeps developing quickly, the demand for smart, efficient pre-engineered solutions will only increase, securing their role as the future of construction.

FAQs

1. What is an example of a pre-engineered building?

Common examples of pre-engineered steel buildings include large warehouses, factory sheds, metro stations, airport hangars and modern retail showrooms.

2. What is the difference between PEB and RCC buildings?

The primary difference lies in the material and construction method. PEB uses steel as its primary structural material, with components fabricated in a factory and assembled on-site. RCC (Reinforced Cement Concrete) buildings use a framework of concrete and steel rebar, which is constructed entirely on-site. Peb construction is significantly faster, lighter and more flexible than RCC construction.

3. What is the life expectancy of a PEB structure?

A well-designed and properly maintained pre-engineered building can have a life expectancy of 50 years or more. The longevity depends on factors like the quality of the materials, the environmental conditions and the regularity of maintenance.

5 Responses

I found the blog to be very insightful It provided a clear explanation of pre-engineered buildings, highlighting their efficiency and cost-effectiveness in modern construction. I appreciate the detailed breakdown of the benefits and customizable options that are available. This is a must-read for anyone who is considering innovative construction solutions.

“Thanks for sharing this information by reading this blog! if anyone require Pre Engineered Buildings or a PEB Plant. We would be happy to help and offer similar services.

Buildmate:https://www.buildmate.in/pre-engineered-buildings.php

Pre-engineered buildings, or PEBs, are transforming the Indian construction sector with their sustainable and effective methodology. Due to the fact that the steel components for these buildings are planned and produced in factories before being assembled on location, material waste and cost are greatly decreased. They are extremely durable and resistant to harsh weather. PEBs can be tailored and made to fit a variety of architectural styles. An outstanding example that combines strength and style is Pune’s Aluminum Standing Roofing System. PEBs are starting to take the lead in India’s new construction projects thanks to these benefits.

Pre-Engineered Buildings (buildmate) represent a significant advancement in the construction industry, offering numerous benefits over traditional building methods. These structures are meticulously designed and fabricated in a factory, ensuring high precision and quality control. One of the standout features of PEBs is their cost-effectiveness. By minimizing material wastage and reducing construction time, PEBs provide substantial savings in both material and labor costs.

Nice blog. Thank you

Pre engineered building manufacturers in Hyderabad