Highlights

- Pre-Engineered Buildings (PEBs) are revolutionising warehousing with faster, cost-effective, and sustainable construction methods.

- The future of pre-engineered buildings is driven by technological advancements like BIM and a growing demand in sectors like e-commerce and logistics.

- PEB warehouses offer superior versatility, durability, and ease of maintenance compared to traditional construction.

- When comparing PEB to traditional methods, PEBs excel in speed, quality control, cost-efficiency, and scalability.

Understanding the Future of PEB Warehousing

Gone are the days of months-long projects, built out of brick, cement and sweat. We are ushering in an era of efficiency and sustainability through the engineering marvel that is pre-engineered buildings. Welcome to the future of Indian warehousing. The logistics and supply chain industry is the backbone of a growing economy, with the warehouse at its core. As businesses expand and the demand for faster delivery increases, the need for efficient, scalable and robust warehousing solutions has never been more important. This is where the future of pre-engineered buildings comes into focus, providing a modern solution that surpasses traditional construction methods in every key area.

What is a PEB Warehouse?

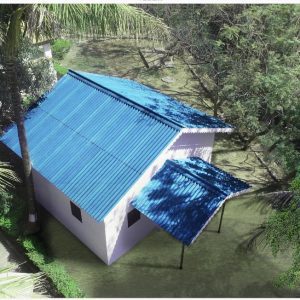

A Pre-Engineered Building (PEB) warehouse is a modern structural solution where the building components are designed and fabricated in a factory-controlled environment before being transported to the construction site for assembly. A warehouse peb structure is precision-engineered using advanced software to meet specific design requirements. Key components include primary frames, secondary frames (purlins and girts) and cladding systems all of which are manufactured to exact specifications, ensuring quality and a perfect fit during erection.

Evolution of Warehousing Solutions

Warehousing has evolved significantly from simple, conventionally built godowns to complex, technologically advanced fulfilment centres. Initially, warehouses were constructed using traditional brick-and-mortar methods, which were time-consuming, expensive and rigid in design. The industrial revolution brought about the use of structural steel, but it was the advent of pre-engineered systems that truly transformed the landscape. This evolution has culminated in the modern pre-manufactured warehouse, a solution designed for the speed and dynamism of today’s market.

Why are PEB Warehouses the Future?

The rapid adoption of PEB technology is not a fleeting trend; it is a fundamental shift in how we approach industrial construction. The advantages are clear, making it the definitive choice for modern warehousing.

Large Markets for PEB in India

India’s booming e-commerce, manufacturing, and 3PL (Third-Party Logistics) sectors are fuelling an unprecedented demand for large-scale, efficient warehousing spaces. India is one of the largest economies in the world, with hundreds of industries driving its economic growth. Most of these industries have very specific warehousing requirements. Pre-engineered buildings are here to fulfil those requirements, with their ease of installation and quick turnaround time.

From textiles to pharmaceuticals, warehouse PEB structures can be customised to every need, aiding in temperature control, weather-proofing and chemical resistance. In this high-growth environment, speed-to-market is a critical competitive advantage. The peb warehouse construction methodology directly addresses this need, allowing companies to set up massive facilities in a fraction of the time required for traditional buildings. This makes PEB the ideal solution for businesses looking to expand their

Technology Trends

As automation takes the reins, warehouse management systems are getting increasingly effective at speeding up everyday processes. And while you are revolutionising the inside of your warehouse, why not give the same thought to the outside too? Pre-engineered buildings can help you automate the construction process and erect strong, stable structures in much less time than traditional construction. The future of pre-engineered buildings is deeply intertwined with technology. Advanced design software and Building Information Modeling (BIM) are central to the peb warehouse design process. These technologies allow for the creation of precise 3D models, enabling architects and engineers to optimise structural integrity, minimise material wastage and prevent clashes before a single piece of steel is fabricated. This digital-first approach ensures accuracy, enhances collaboration and streamlines the entire construction lifecycle.

Truly Versatile

One of the most significant benefits of a warehouse peb structure is its immense versatility. PEB designs can achieve massive, column-free clear spans, providing unobstructed floor space that is essential for modern material handling equipment and racking systems. Furthermore, these structures are inherently modular. Expanding a pre-manufactured warehouse is as simple as adding new bays, a process that is far more complex and costlier with conventional buildings. This scalability makes PEBs a future-proof investment for growing businesses.

Ease of Maintenance

The use of high-quality, durable materials in PEB warehouse construction minimises the need for frequent repairs, reducing downtime and associated costs. Additionally, the absence of complex structural components like excessive columns or beams simplifies inspections and maintenance tasks.

With easy access to components and straightforward maintenance procedures, PEB warehouses exemplify a practical and low-maintenance choice for companies aiming for long-term operational efficiency.

PEB vs Traditional Warehouse – Which is better?

When deciding on the construction of a new warehouse, the choice between PEB and traditional methods is a critical one. Here’s a direct comparison:

- Construction Speed: PEB construction can be up to 50% faster than traditional construction. Since fabrication occurs off-site in parallel with foundation work, on-site assembly is rapid and efficient.

- Cost-Effectiveness: The optimised peb warehouse design process reduces steel consumption. Additionally, faster construction times and reduced labour requirements lead to significant overall cost savings.

- Quality Control: PEB components are manufactured in a controlled factory environment using automated machinery, ensuring consistent quality and adherence to strict standards. This is a level of precision that is difficult to achieve in on-site traditional construction.

- Design Flexibility: While traditional construction offers design freedom, PEBs provide unmatched flexibility for industrial applications. Large clear spans, customised heights, and the ease of future expansion give PEBs a distinct advantage for warehousing.

- Sustainability: Steel is one of the most recycled materials on earth. The peb warehouse construction process minimises waste and the buildings can be designed to be highly energy-efficient, making them a more environmentally friendly choice.

For businesses that prioritise speed, cost, quality and scalability, the pre-manufactured warehouse is the clear winner.

FAQs

1. What is a PEB warehouse?

A PEB (Pre-Engineered Building) warehouse is a contemporary warehousing solution built using pre-designed and pre-fabricated steel components. These components are manufactured off-site and transported to the construction site for quick assembly. This approach enables faster construction, improved cost efficiency and greater durability compared to conventional building methods.

2. Are PEB warehouses cost-effective compared to traditional construction for warehouses?PEBs

Yes, absolutely. PEB warehouses are highly cost-effective due to several factors: optimised use of steel, reduced raw material waste, lower labour costs because of faster assembly, and quicker project completion times, which leads to a faster return on investment.

3. How do PEBs contribute to sustainability in warehousing?

PEBs are inherently sustainable. The primary material, steel, is highly recyclable. The factory-controlled manufacturing process drastically reduces on-site construction waste. Furthermore, PEB structures can be easily integrated with energy-saving solutions like solar panels, skylights and insulated panels, reducing the building’s operational carbon footprint.

4. What are the key considerations for companies looking to transition to PEBs for their warehousing needs?

Companies should consider the following:

Clear Requirements: Define the specific needs regarding size, height, load requirements and future expansion plans.

Site Readiness: Ensure the site is properly prepared for the foundation and assembly process.

Choosing the Right Partner: Select an experienced and reputable PEB solutions provider like Everest Steel Building Solutions, who can manage the entire process from design and fabrication to final erection.

5. Can existing warehouses be retrofitted with PEB elements for modernisation?

Yes, existing warehouses can be retrofitted with PEB elements to modernise and optimise their functionality. This cost-effective approach allows businesses to upgrade their facilities without the need for a complete reconstruction, adapting to the changing needs of the industry.

One Response

Great post. I was checking continuously this blog and I’m impressed!

Extremely helpful info particularly the last part 🙂

I care for such information a lot. I was looking for this particular information for a very long

time. Thank you and good luck.